Views: 0 Author: Site Editor Publish Time: 2025-12-22 Origin: Site

High-Purity Barium Carbonate is a chemical compound with significant industrial applications, including in the manufacturing of ceramics, glass, and specialty chemicals. Its unique properties make it indispensable in various sectors, yet its handling, storage, and transportation require stringent safety measures. This article delves into the comprehensive guidelines for the safe storage, transportation, and handling of High-Purity Barium Carbonate, ensuring that industries can utilize this compound effectively while minimizing risks. For more detailed information on the applications and properties of Barium Carbonate, you can explore the Barium Carbonate section on our website.

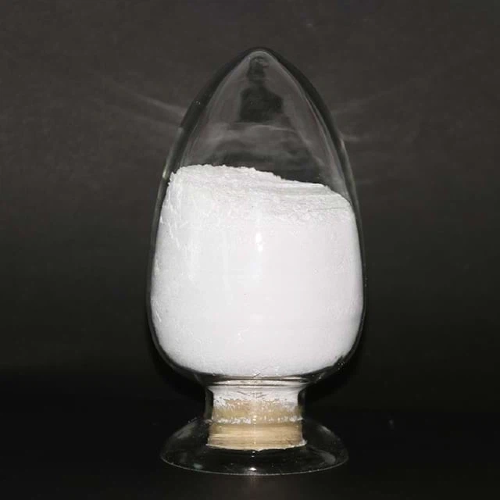

High-Purity Barium Carbonate is characterized by its high purity level, which is crucial for its effectiveness in sensitive applications. The compound is typically found in a white powder form, with a molecular weight of 197.34 g/mol. It is insoluble in water but soluble in acids, making it a versatile component in chemical reactions. The purity of Barium Carbonate directly influences its reactivity and suitability for high-precision industrial processes.

The chemical stability of High-Purity Barium Carbonate under normal conditions makes it relatively safe to handle, provided that standard safety protocols are followed. Its reactivity with acids, however, necessitates careful handling to prevent unintended reactions. Understanding these properties is essential for industries that rely on Barium Carbonate for their manufacturing processes.

Proper storage of High-Purity Barium Carbonate is critical to maintaining its quality and preventing contamination. The compound should be stored in a cool, dry place, away from any sources of moisture or acids that could trigger a reaction. Containers used for storage must be airtight and made of materials that do not react with Barium Carbonate.

The storage area should be well-ventilated to prevent the accumulation of any dust particles, which could pose inhalation risks. Additionally, it is important to label storage containers clearly, indicating the contents and any potential hazards. Regular inspections of the storage facilities can help identify any issues early, ensuring that the compound remains in optimal condition for use.

For companies looking to optimize their storage solutions, consulting with experts in chemical storage can provide valuable insights. More information on the safe storage of chemical compounds can be found on our products page.

Transporting High-Purity Barium Carbonate requires adherence to specific regulations to ensure safety and compliance. The compound should be transported in sealed containers that are resistant to impact and environmental conditions. During transportation, it is crucial to avoid any exposure to moisture or acids, which could compromise the integrity of the compound.

Transport vehicles should be equipped with safety measures, including spill containment systems and appropriate signage indicating the nature of the cargo. Drivers and handlers must be trained in the proper procedures for dealing with any incidents that may occur during transit. This includes having access to Material Safety Data Sheets (MSDS) and emergency contact information.

Adhering to these guidelines not only ensures the safety of personnel involved in the transportation process but also minimizes the risk of environmental contamination. For detailed guidelines on the transportation of chemical compounds, visit our industries section.

Handling High-Purity Barium Carbonate requires strict adherence to safety protocols to prevent exposure and contamination. Personnel should wear appropriate personal protective equipment (PPE), including gloves, masks, and eye protection, to minimize the risk of inhalation or skin contact. Work areas should be equipped with ventilation systems to reduce the concentration of airborne particles.

Training is essential for all personnel involved in the handling of Barium Carbonate. This includes understanding the properties of the compound, potential hazards, and emergency response procedures. Regular drills and safety audits can help reinforce these protocols and ensure that staff are prepared to handle any incidents effectively.

Implementing these handling guidelines not only protects workers but also ensures the quality and integrity of the compound throughout its use. For more information on handling practices, please refer to our case studies section.

Compliance with regulatory standards is crucial in the storage, transportation, and handling of High-Purity Barium Carbonate. Organizations must adhere to local and international regulations, which govern the safe management of chemical compounds. This includes obtaining necessary permits and ensuring that all practices meet the required safety standards.

Environmental considerations are also paramount. Companies must implement measures to prevent any accidental release of Barium Carbonate into the environment, which could have detrimental effects on ecosystems. This involves having robust spill response plans and waste management systems in place.

Staying informed about regulatory changes and advancements in environmental protection can help organizations maintain compliance and adopt best practices. For further details on regulatory compliance, visit our privacy policy page.

In conclusion, the safe storage, transportation, and handling of High-Purity Barium Carbonate are essential to maximizing its industrial benefits while minimizing risks. By adhering to the guidelines outlined in this article, industries can ensure the effective use of this compound in their operations. Ongoing training, regular audits, and a commitment to safety and environmental protection are key to maintaining high standards in the management of Barium Carbonate.

For more comprehensive resources and expert advice on managing chemical compounds, explore our High-Purity Barium Carbonate section.