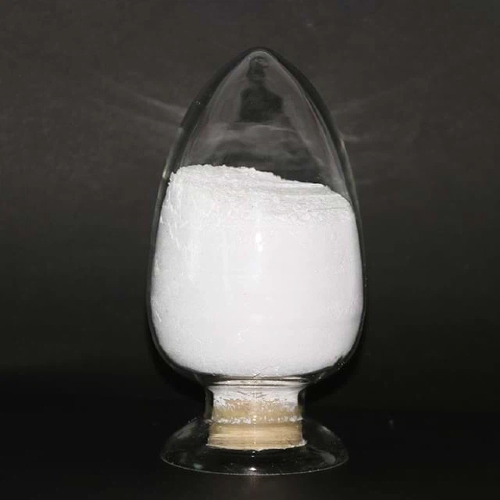

Zinc Stearate is a widely used chemical compound with versatile applications across numerous industries, including plastics, rubber, coatings, cosmetics, and pharmaceuticals. Chemically, it is a zinc salt of stearic acid, appearing as a fine white powder that is insoluble in water but soluble in organic solvents. It functions primarily as a lubricant, release agent, anti-caking agent, and processing aid.

Understanding Zinc Stearate is crucial for manufacturers, formulators, and consumers because it directly affects product quality, manufacturing efficiency, and safety. Its multifunctional properties allow it to improve processing efficiency, reduce wear on machinery, and enhance the quality of the final product. Moreover, the chemical’s inertness ensures compatibility with a wide range of materials without altering the underlying chemical structure. In this guide, we will explore its chemical properties, industrial and consumer applications, safety considerations, regulatory standards, and tips for safe handling. By the end, readers will have a comprehensive understanding of Zinc Stearate and its role in modern manufacturing.

Zinc Stearate is composed of two stearate ions bound to a zinc ion, giving it the chemical formula Zn(C18H35O2)2. Stearic acid, a long-chain saturated fatty acid, contributes to the compound’s waxy texture and hydrophobic properties, which are key to its function as a lubricant and anti-caking agent. The molecular structure ensures that it remains chemically stable under normal conditions and does not react adversely with other substances in formulations, which is critical in industries that require high purity and chemical consistency.

The physical characteristics of Zinc Stearate are essential for understanding its behavior in different applications.

Property | Description |

Appearance | Fine white, waxy powder |

Chemical Formula | Zn(C18H35O2)2 |

Solubility | Insoluble in water; soluble in non-polar organic solvents such as benzene, chloroform, and xylene |

Melting Point | 120–130°C |

Stability | Stable under normal conditions; resistant to moisture, oxidation, and mild heat |

Odor | Odorless |

The compound’s waxy texture and low solubility in water make it suitable for coating particles and polymer surfaces, reducing friction and preventing caking. Its stability at high temperatures also allows it to function effectively during thermal processing without breaking down or producing harmful byproducts.

Zinc Stearate is primarily valued for its lubricating, release, and anti-caking properties, making it a critical additive in many manufacturing processes. When incorporated into formulations, it acts as a surface-active agent, forming a very thin, uniform layer over particles, polymer chains, or processing surfaces. This microscopic coating effectively reduces mechanical friction, allowing materials to flow more smoothly during extrusion, molding, or compounding. The reduced friction not only improves processing efficiency but also minimizes wear and tear on machinery, contributing to longer equipment life.

In addition to its lubrication role, Zinc Stearate is chemically inert under normal processing conditions. This means it does not react with other additives, fillers, or base materials, maintaining the integrity of the final product while enhancing performance. Its hydrophobic nature also helps repel moisture, which is especially beneficial for maintaining stability in powders and preventing unwanted clumping.

Lubrication: By forming a thin film on surfaces, Zinc Stearate reduces resistance between moving parts or particles. This decreases energy consumption during manufacturing and ensures consistent material flow, which is essential for high-quality end products.

Release Agent: Its low surface energy and hydrophobic characteristics prevent adhesion to molds, presses, and other processing equipment. As a result, molded or pressed items release easily, reducing the need for additional mechanical force or chemical release agents.

Anti-Caking: When applied to fine powders, Zinc Stearate forms a barrier that minimizes particle-to-particle interaction and moisture absorption. This property ensures powders remain free-flowing and uniform, which is crucial for precise dosing, blending, and consistent quality in industrial and consumer products.

Zinc Stearate’s unique combination of functional properties makes it highly versatile:

Plastics: Improves flow properties during extrusion or molding and enhances surface finish for a smooth, defect-free appearance.

Rubber: Prevents sticking, disperses fillers evenly, and helps maintain elasticity and uniform texture in final products.

Coatings and Paints: Ensures pigments and powders do not clump, promoting consistent application and high-quality finishes.

Cosmetics: Provides a silky, smooth feel, prevents caking, and absorbs excess oils, improving product usability and shelf life.

Pharmaceuticals: Functions as both a release agent and excipient, maintaining tablet integrity and uniformity during production.

In thermoplastics and thermoset polymers, Zinc Stearate serves as a processing aid and lubricant. By reducing internal friction during extrusion, molding, or pressing, it facilitates smoother polymer flow, lowers production stress, and helps achieve consistent surface quality. It also minimizes material adhesion to equipment, reducing downtime for cleaning and maintenance.

Key Benefits in Plastics:

Improved mold release and reduced sticking

Enhanced surface smoothness and uniformity

Reduced processing pressure and friction

High-temperature stability to prevent degradation

Zinc Stearate’s lubricating and anti-sticking properties make it valuable in rubber compounding. It improves the uniform distribution of fillers, aids in achieving consistent elasticity, and prevents raw rubber sheets or molded items from adhering to production equipment. The resulting rubber products have more uniform physical properties, making them suitable for industrial and consumer applications.

In coatings, powders, and paints, Zinc Stearate acts as an anti-caking and flow agent, ensuring even dispersion of pigments and additives. Its hydrophobic nature prevents moisture absorption, maintaining product stability during storage. It also improves flow characteristics, allowing for smooth, uniform application and a consistent finish.

Zinc Stearate is extensively used in cosmetics for its anti-caking, texturizing, and oil-absorbing properties. Its fine particle size allows it to blend seamlessly into formulations, enhancing product feel and stability. Powders, blushes, eyeshadows, and pressed makeup maintain uniformity and are easier to handle and apply. Additionally, it helps reduce greasy residue by absorbing excess oils on the skin.

In pharmaceuticals, Zinc Stearate is occasionally employed as a tablet excipient or release agent. Its chemical inertness and stability ensure that it does not interfere with active ingredients or drug efficacy. It also aids in manufacturing efficiency by preventing sticking to molds and presses. Regulatory compliance ensures its safety in this application.

Zinc Stearate is considered generally safe, but certain precautions should be observed:

Skin Contact: Prolonged exposure to large quantities of powder may cause mild irritation, dryness, or discomfort.

Inhalation: Breathing in fine particles may irritate the respiratory system. Proper ventilation and PPE, such as masks, are recommended in industrial settings.

Ingestion: Zinc Stearate is low in acute toxicity, but ingestion of large amounts may cause gastrointestinal discomfort.

Zinc Stearate is environmentally low-risk due to its insolubility in water and minimal bioaccumulation. Although it degrades slowly, industrial waste management is recommended to prevent accumulation in soil or water systems. Its use in coatings, plastics, and cosmetics generally poses limited environmental impact under controlled disposal practices.

Application | Risk Level | Notes |

Industrial processing (plastics/rubber) | Medium | Dust inhalation possible; PPE recommended; air monitoring advised |

Cosmetics | Low | Safe in regulated concentrations; minimal risk of irritation |

Pharmaceuticals | Low | Considered safe as an excipient; must comply with regulatory limits |

Food contact (indirect) | Very Low | Approved in small quantities for indirect food contact; safe under guidelines |

Zinc Stearate is regulated under multiple international frameworks:

FDA (U.S.): Recognized as GRAS (Generally Recognized as Safe) for indirect food contact and pharmaceutical applications.

EU REACH: Registered and deemed safe under defined exposure limits.

OSHA (U.S.): Provides occupational exposure limits for dust to protect workers in industrial environments.

Use personal protective equipment (PPE), including gloves, masks, and goggles, when handling powders.

Ensure adequate ventilation in production and processing areas.

Store in sealed, dry containers, away from moisture and strong oxidizers.

Train personnel in safe handling procedures, emergency protocols, and proper disposal methods.

Zinc Stearate is a versatile and widely used chemical additive, playing a crucial role in industries such as plastics, rubber, coatings, cosmetics, and pharmaceuticals. When used according to proper safety practices and regulatory standards, it is considered safe for both industrial and consumer applications. Its low toxicity, chemical stability, environmental compatibility, and multifunctionality make it an essential material in modern manufacturing.

For those looking to source high-quality Zinc Stearate or seeking professional guidance on its applications and specifications, Qingdao Red Butterfly Precision Materials Co., Ltd. offers reliable solutions and expert support. Their team can provide technical advice, product selection assistance, and customized solutions to meet specific manufacturing needs. To explore their range of products and services or discuss potential collaboration, reaching out directly to the company is highly recommended.

What is zinc stearate used for?

Zinc Stearate functions as a lubricant, release agent, and anti-caking additive in plastics, rubber, coatings, cosmetics, and pharmaceuticals.

Is zinc stearate safe in cosmetics?

Yes, it is safe in regulated concentrations, providing smooth texture, preventing caking, and absorbing excess oils.

Can zinc stearate be inhaled safely?

Inhalation of fine dust should be minimized using PPE and proper ventilation. It may cause mild respiratory irritation but is generally low-risk under controlled conditions.

Is zinc stearate toxic to humans or animals?

Zinc Stearate has low toxicity. Small amounts are safe for skin contact or ingestion, but prolonged exposure to high dust levels should be avoided.

How should zinc stearate be stored and handled?

Store in sealed, dry containers, away from moisture and oxidizers. Use PPE when handling powders, maintain ventilation, and follow regulatory guidelines for safe use.